Additive manufacturing is an innovative and futureoriented process which enables us to convert virtual 3D models into physical objetcts in the shortest possible time and on demand. 3D printing is divided into three categories:

the production of Rapid Prototyping

= the construction of prototypes to quickly assess whether a concept is suitable for serial production.

the production of Rapid Tooling

= the construction of tools, molds and fixtures in order to be able to implement quick one off productions or very small batches. As you purchase the tools for custommade products, you directly benefit from the low manufacturing costs of 3D printing compared to conventional manufacturing methods.

the production of Rapid Manufacturing / Direct Manufacturing

= the construction of individual parts, which are subsequently processed in series or as spare parts. For higher volumes, there are more costeffective systems, but for small batches or oneoffs, the additive manufacturing is the most flexible and costeffective solution. The finished components are then painted with the robust paints used in series production, so that the new component blends seamlessly into the overall look.

In additive manufacturing both filament and granulatebased thermoplastic compounds are used. The material is applied layer by layer according to the computercontrolled specifications of the CAD data.

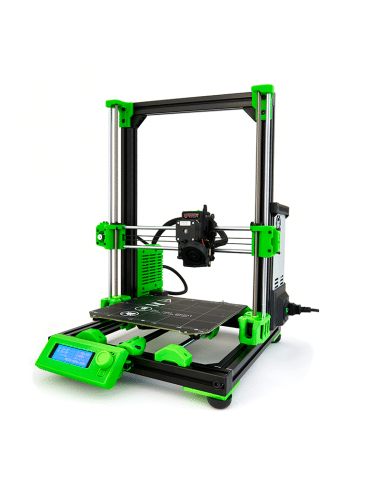

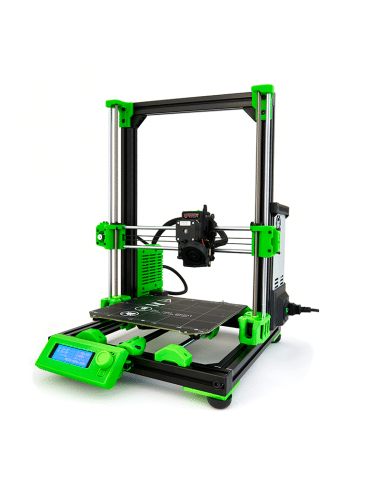

Smallscale additive manufacturing (filament based)

Manufacturing and assembly jigs

- Customized painting template

- Drilling jigs

- Positioning jigs

Components

- Production of obsolescent components

- Spare parts

- Small batches

Materials: PLA, PETG, PETG-CF, ABS, ASA, PP, PA, PA-CF, PC-CF, TPU

Print volume: 250 mm x 210 mm x 400 mm

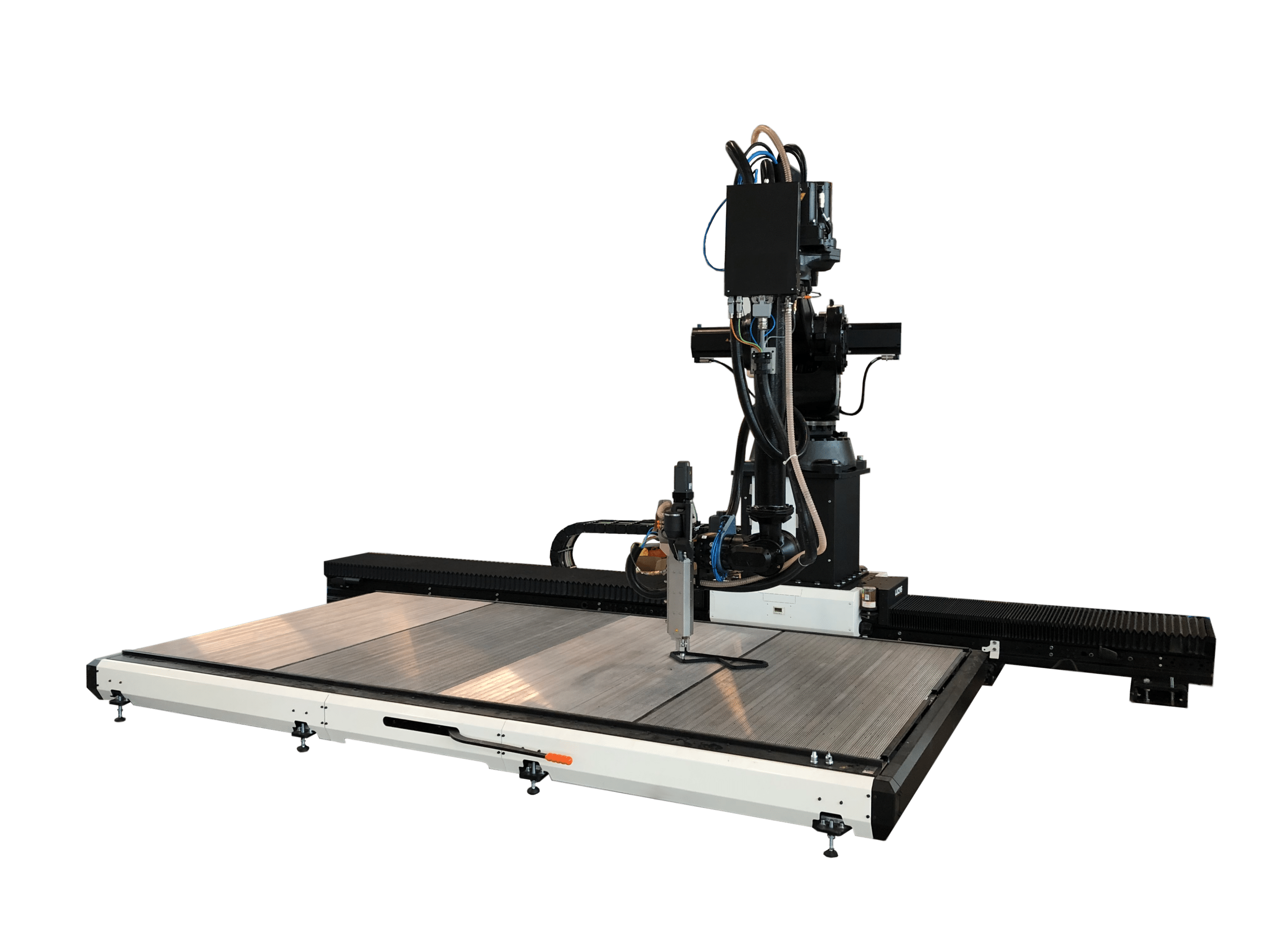

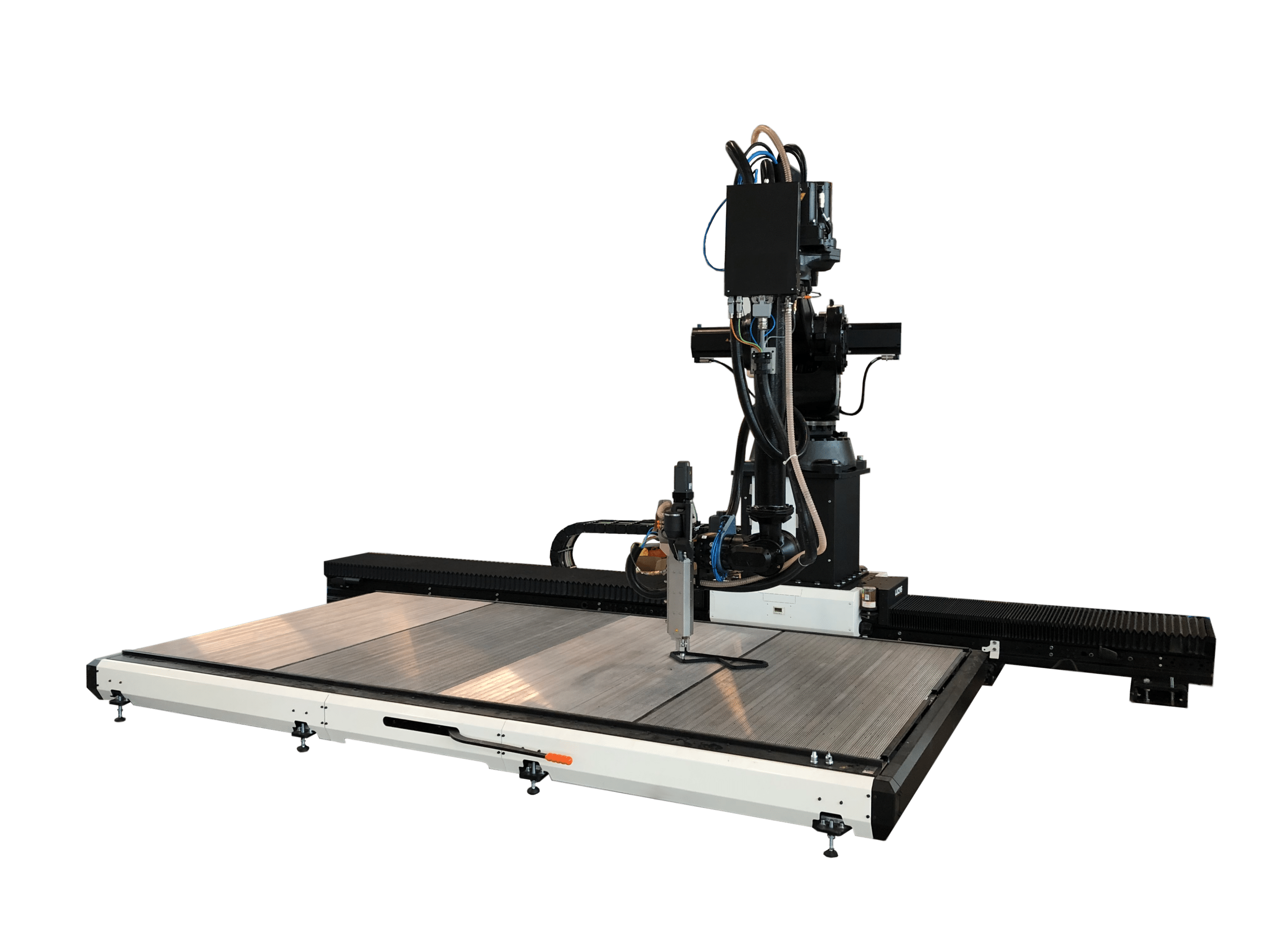

Largescale additive manufacturing using robotic technology (granulate based)

- Large objects made from thermoplastic compounds

- Jig and fixture construction

- Mold construction

- Production of large components

- Subsequent milling of functional surfaces possible

Materials: PP-, PET-, PA-, PC-, ASA-, PPS-Compounds (more possible)

output: up to 15 kg/h

Print bed size: 4m x 2m

Print volume: Depending on the component geometry

Step 1:

Step 1: Step 2:

Step 2: Step 3:

Step 3: