System Supplier

With over 20 years of engineering expertise in development and design, we are one of the market leaders for components in the rail vehicle industry.

Our expertise covers the following areas:

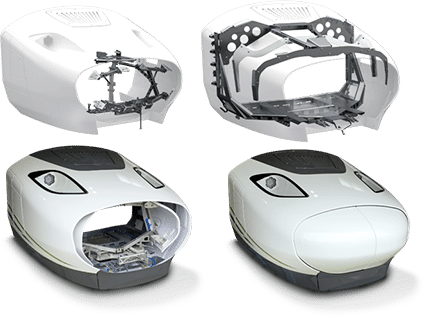

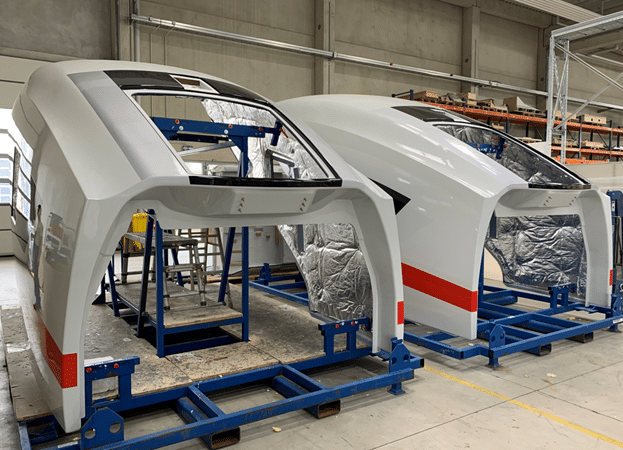

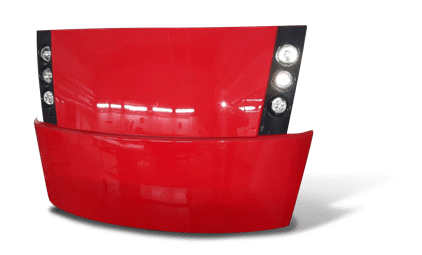

- the production and processing of glass fiber reinforced plastic (GRP)

- the design & development of electronic and electrical systems

- the installation of pneumatic and hydraulic components

And most importantly:

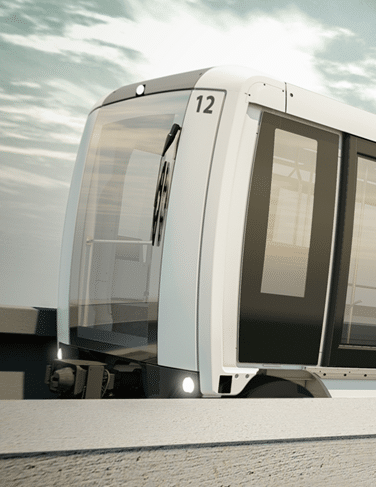

The combination of these three fields in complex and highly technical

modules.

- Perfectly matched

- reliable

- sustainable

The close collaborative partnership with our customers already starts in the product development phase in order to optimally combine the wishes of engineers and designers with the material and manufacturing related possibilities. This allows us to produce costoptimized, efficient & highquality products / system components: Everything from one source (plug & play), from concept to retrofit.

Learn more about our components and service!